BIOMATERIALS

Why in Focus?

- Countries are shifting towards cleaner and low-carbon manufacturing for plastics, textiles, and consumer products.

- Biomaterials are emerging as a key alternative to fossil-based materials.

- For India, indigenous biomaterials can reduce import dependence, support farmers, and help meet climate and waste reduction goals.

WHAT ARE BIOMATERIALS?

- Biomaterials are materials that are derived fully or partly from biological sources or are engineered using biological processes.

- They are designed to replace or interact with conventional materials, especially petroleum-based ones.

- Biomaterials are increasingly used in packaging, textiles, construction, healthcare, and consumer goods.

TYPES OF BIOMATERIALS

1. Drop-in Biomaterials

- These are chemically identical to fossil-based materials.

- They can be used in existing manufacturing systems without major changes.

- Example: Bio-PET (used in bottles and packaging).

2. Drop-out Biomaterials

- These are chemically different from petroleum materials.

- They require new processing methods or new end-of-life systems.

- Example: Polylactic Acid (PLA), which needs industrial composting.

3. Novel Biomaterials

- These offer new properties not found in conventional materials.

- Examples include self-healing materials, bioactive medical implants, and advanced bio-composites

- They open new possibilities in healthcare, defence, and advanced manufacturing.

WHY DOES INDIA NEED BIOMATERIALS?

- India depends heavily on fossil-based imports for plastics, chemicals, and materials.

- Indigenous biomaterials can reduce import bills and improve energy security.

- They provide new income sources for farmers by using agricultural crops and residues beyond food markets.

- Biomaterials align with India’s goals of:

- Banning single-use plastics,

- Reducing waste,

- Meeting climate action commitments,

- Remaining competitive in global export markets where low-carbon products are preferred.

CURRENT STATUS OF BIOMATERIALS IN INDIA

- India’s biomaterials sector is rapidly emerging, especially in bioplastics and biopolymers.

- The Indian bioplastics market was valued at around $500 million in 2024 and is expected to grow strongly.

- Major developments include:

- Balrampur Chini Mills’ PLA plant in Uttar Pradesh, one of India’s largest investments in this sector.

- Startups like Phool.co, which converts temple flower waste into biomaterials.

- Praj Industries, which is developing a demonstration-level bioplastics plant.

- Despite strong agricultural capacity, India still depends on foreign technologies in some stages of converting biomass into finished materials.

HOW WILL BIOMATERIALS REDUCE FOSSIL BASED IMPORT DEPENDANCE?

- They replace petroleum-based plastics and chemicals with bio-derived alternatives.

- They use domestic agricultural feedstocks such as sugarcane, maize, and crop residues.

- They help shift India from being an importer of materials to a producer of bio-based value-added products.

- Over time, this strengthens industrial self-reliance and supply-chain resilience.

CHALLENGES IN SCALING BIOMATERIALS IN INDIA

- Feedstock competition may arise if demand increases faster than agricultural productivity

- Intensive farming for biomass could cause water stress and soil degradation.

- Weak waste-management and composting infrastructure may limit environmental benefits.

- Fragmented policy coordination between agriculture, environment, and industry can slow progress

- Delays in scaling could make India dependent on imports, while other countries move ahead faster.

WAY FORWARD FOR INDIA

- Expand biomanufacturing infrastructure, especially fermentation and polymerisation capacity.

- Improve feedstock productivity using advanced agricultural and biotech methods.

- Invest more in research and development, especially for novel biomaterials.

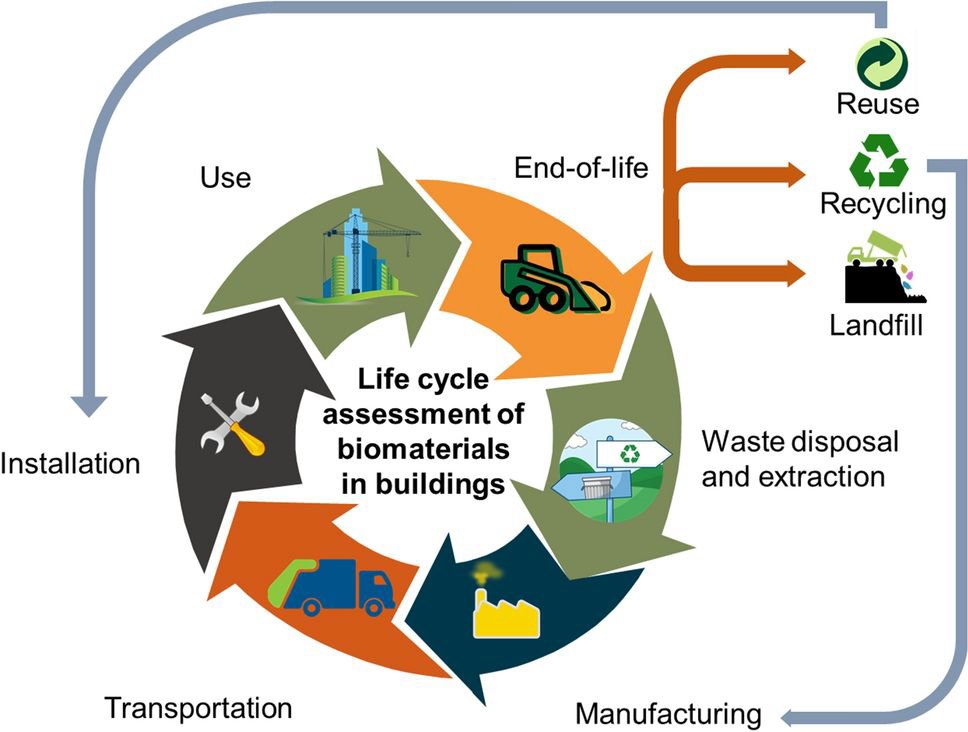

- Establish clear regulatory definitions, labelling rules, and end-of-life pathways such as recycling or industrial composting.

- Use government procurement, time-bound incentives, and pilot projects to reduce early investment risks.

- Promote shared facilities and demonstration plants to help startups and MSMEs scale faster.

CONCLUSION

- Biomaterials offer India a single pathway to achieve environmental sustainability, industrial growth, farmer welfare, and import reduction.

- India has strong natural and industrial advantages, but scaling infrastructure, policy coordination, and waste systems is critical.

- Timely action can position India as a global leader in bio-based materials, rather than a late adopter dependent on foreign technologies.

Note: Connect with Vajirao & Reddy Institute to keep yourself updated with latest UPSC Current Affairs in English.

Note: We upload Current Affairs Except Sunday.

The post BIOMATERIALS appeared first on Vajirao IAS.